Traverse Global v11.2 - Service Repair

Generate Orders From Sales

If you want to automatically generate production orders based on current sales order demand, use the Generate Orders from Sales function in conjunction with the Sales Order Analysis report. The Generate Orders from Sales function uses the same logic as the Sales Order Analysis report when looking at existing sales orders and generating production orders from them, except it creates production orders instead of just reporting what orders will be created. Only sales orders with a status of 'New', 'Picked', or 'Backordered' are considered. The sales order item must be a legitimate inventory item and have a bill of material (BOM) in the manufacturing BOM master table.

Generate Orders process

The process to automatically generate production orders based on current sales order demand considers these values when determining current demand for an item:

- Total Quantity Ordered (SO)

- Total Quantity Shipped (SO)

- Total on Order (MP)

- Total in Process (MP)

- Total Quantity Produced (MP)

Because there are no direct links between Sales Order and MFG - Production, the quantity to produce is calculated using these quantities:

- The greater of SO Total Shipped and MP Produced quantities

- Decreases the total quantity demand

- Presumes that if more units have been shipped than have been produced, some must have come from stock and do not need to be created

- If more units have been produced than have been shipped, those units are available for shipping and do not need to be created

- The greater of MP On Order and MP In Process quantities

- Decreases the total quantity demand

- This accounts for scenarios in which more production has been recorded for an order than the original order quantity

Note: The use of Shipped vs Produced quantities may switch back and forth when working with multiple partial shipments/production completion cycles. This is a known limitation that cannot be addressed without a more direct connection between SO/MP orders.

Sample Calculation:

- QtyToProduce = The quantities that need to be created.

- SOOrderQty = The total SO order quantity for the given assembly and location on a single SO transaction.

- SOShipQty = The total SO shipped quantity for the given assembly and location on a single SO transaction.

- MPOrderQty = The total order quantity of all incomplete MP orders related to a single SO transaction.

- MPInProcessQty = The total recorded quantities of finished goods of all incomplete MP orders related to a single SO transaction.

- MPProducedQty = The total recorded quantities of finished goods of all complete MP orders related to a single SO transaction.

QtyToProduce = the greater of [SOOrderQty - (greater of MPOrderQty or MPInProcessQty) - (greater of SOShipQty or MPProducedQty)] or 0

NOTE: If you have more complex needs than those that can be addressed by using the Generate Orders from Sales function, consider using the Requirements Planning application.

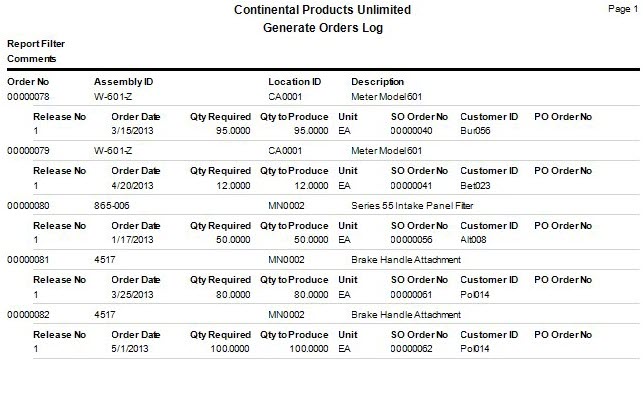

As this function creates production orders, it creates them with a status of 'Planned' (Planned = New). Print the Sales Order Analysis report to check for production orders that appear to be generated for sales orders but may not have the same due date or quantities.

An order with a 'Planned' status is a tentative order. If the status is not changed to 'Firm Planned' or 'Release', the order will be automatically purged the next time the Generate Order process is run. The first task of the Generate Order function is to purge all production orders with a status of 'Planned' AND that fall within the date range selected, thus it is important that you carefully select the date range OR change the status to 'Firm Planned' or 'Release'. If an order is within the selected date range and its status is 'Planned', it will simply get deleted and recreated with a different production order number; however this may or may not be something you want to have happen. Also note that if a given sales order contains multiple entries for the same product ID and the selected date range is broad enough to include these lines of the sales order, the production order will get created as one order with multiple releases.

- Use the Data Filter to select the range of filtering options or leave the filter blank to include all available data.

- Enter any applicable comments in the Comments field.

-

Click a command button to

Click To Execute Generate production orders using the selected filtering options. Activity View the Activity Log for generating orders from sales. Reset Set all fields to their default values