Traverse Global v11.2 - Service Repair

Using Tolerances in Configurator and Inspections

When performing inspections, you must often determine the serviceability of a part by comparing various measurements against a range of values provided by the manufacturer. If a measurement is outside the range recommended by the manufacturer, the part must be repaired or replaced.

Traverse includes this capability via tolerance tables and the Configurator. When you create an inspection using the Configurator, you can create questions that will compare measurements entered by a technician to tolerances entered in tolerance tables.

Creating a Tolerance Table

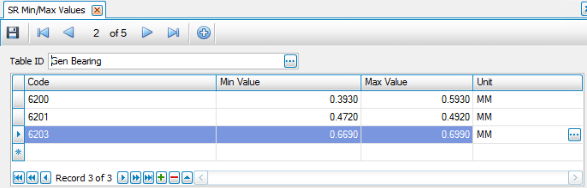

In the Service Repair Inspections menu, the Min/Max Values function allows you to establish tolerance tables used to compare measured values to serviceable ranges. You can create a tolerance table for every set of tolerances you use. For instance, you might have to determine the serviceability of a number of bearings with different part numbers. Each part number might have tolerances different than another. A tolerance table allows you to enter a min/max range of measurements for each different bearing--each part number has its own entry in the table.

Enter a record for each min/max range you want to measure. For this example, we will enter bearing wear tolerances into a single table.

NOTE: In the SM business rules under Numeric Formatting Precision, the Measurements option allows you to define the precision in the tolerance tables.

In the Min/Max Values function:

- Click New to create a new tolerance table.

- Enter a name for the tolerance (min/max) table in the Table ID field.

- Enter a Code for the min/max range. This can be a part number, location indication, or other value identifying the range. For our example, the code is a bearing part number.

- Enter the minimum allowed value for the measurement in the Min Value field.

- Enter the maximum allowed value for the measurement in the Max Value field.

- Select a Unit of measure, as appropriate. If the unit of measure you need does not appear in the drop-down list, you can double-click the unit field to open the Inventory UOMs screen, where you can add a unit of measure to use.

Repeat Steps 2 through 6 for each tolerance range record you want to add to the table. When you are finished, click Save.

Add a Measurement Question to an Inspection using Configurator

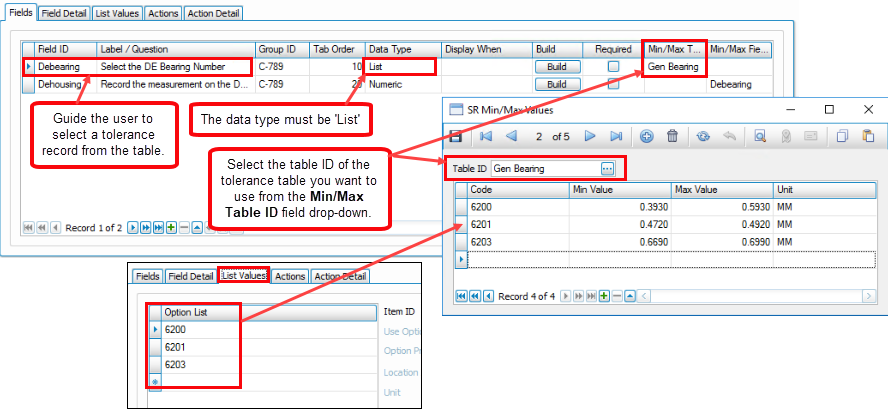

To reference the min/max values in the tolerance table(s), you must add a reference to the appropriate table into the inspection, which is created using the Configurator. This is a two-step process:

Step 1: When creating questions for a group, add a question that leads the user to choose a value from the Code column in a tolerance table.

- Append a new record to the Fields tab.

- Enter a short name or ID for the question being asked in the Field ID field. It is not the actual question. This field is limited to 50 characters.

- In the Label/Question field, instruct the user to select the appropriate record from the tolerance table.

- Select ‘List’ in the Data Type field (you can add the field to the grid using the Column Chooser, if necessary).

- In the Min/Max Table ID field, select the tolerance table that holds the min/max values to which you want to compare. The codes in the tolerance table will appear in the Option List on the List Values tab.

- Save your changes.

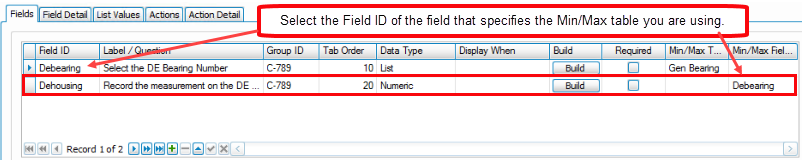

Step 2: Now create the question for which the user will record the measurements.

- Append a new record to the Fields tab.

- Enter a short name or ID for the question being asked in the Field ID field. It is not the actual question. This field is limited to 50 characters.

- In the Label/Question field, instruct the user to record the appropriate measurement.

- Select ‘Numeric’ in the Data Type field.

- In the Min/Max Field ID field, select the Field ID that points to the tolerance (min/max) table.

- Save your changes.

NOTE: Make sure you validate the configuration before you continue.

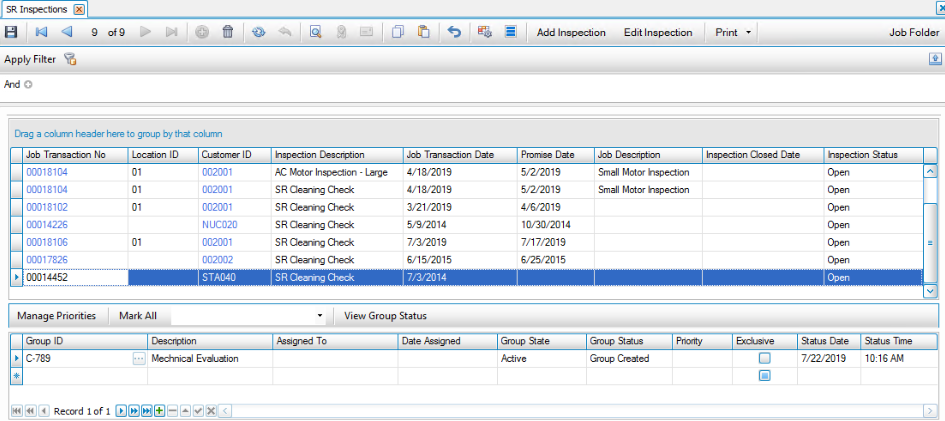

Entering Measurements

You can review the min/max values when you enter measurements. If you are entering measurements on the mobile shop floor app, the minimum and maximum value will be displayed. A visual indication will notify you if the measurement falls within or outside of the range.

On the desktop client, there is no visual indication as to whether the measurement falls within the range. However, you can see the min/max values from the tolerance table when you use the Edit Inspection function from the Inspections screen

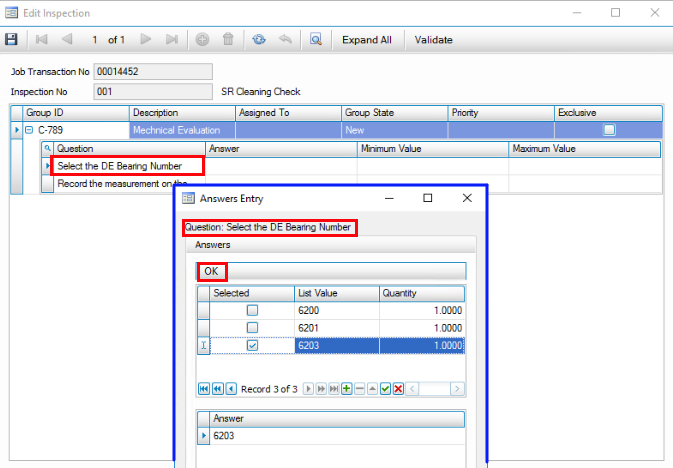

- Open the Inspections screen and select a job transaction that has the inspection with the group that includes the measurement in question attached.

- Click Edit Inspection. The Edit Inspection screen opens. Expand a group by clicking the plus sign next to the group ID or click Expand All.

- Use the Column Chooser to add the Minimum Value and Maximum Value columns to the grid if necessary.

- Click in the Answer field to open the Answers Entry window. Select an option from the list values, then click OK.

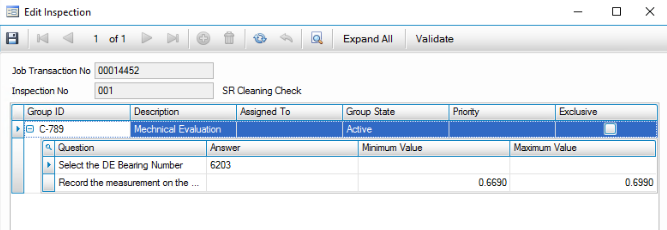

- In the Edit Inspections screen, the grid now shows the min and max values from the min/max table. Enter the appropriate measurement in the Answer field.

- Validate and save your changes. Close the Edit Inspection window to return to the Inspections screen.